Enhance Control: Explore the Versatility of Limit Switch Enabled Ball Valves

By:Admin

[City], [Date] – Leading industrial solution provider [Company Name] has unveiled its latest offering, the Ball Valve With Limit Switch, designed to revolutionize the industrial sector with its advanced features and enhanced functionality. The introduction of this cutting-edge technology underlines the company's commitment to delivering high-performance products that prioritize both efficiency and safety.

The Ball Valve With Limit Switch complies with international quality standards and has been meticulously engineered to meet the diverse needs of industries such as oil and gas, chemical production, water treatment, and many more. By leveraging the latest advancements in technology, [Company Name] has created a comprehensive solution that improves operational performance, minimizes downtime, and ensures maximum safety.

One of the standout features of the Ball Valve With Limit Switch is its integrated limit switch mechanism. This innovative addition allows for remote control and monitoring of valve position, eliminating the need for manual intervention in critical situations. The limit switch is designed to send real-time feedback regarding the valve's position, enabling quick identification of any operational anomalies or potential failures.

Furthermore, the Ball Valve With Limit Switch incorporates a fail-safe mechanism, which ensures that in the event of power failure or other critical malfunctions, the valve automatically goes into a predetermined position that guarantees the safety of operation. This built-in safety feature acts as an added layer of protection, minimizing the risk of accidents and ensuring uninterrupted workflow.

The high-quality materials used in manufacturing the Ball Valve With Limit Switch provide exceptional resistance to harsh operating conditions such as extreme temperatures, corrosive fluids, and high-pressure environments. Its durable construction ensures long-lasting performance and minimal maintenance requirements, reducing operational costs significantly.

[Company Name], known for its expertise in industrial solutions, prides itself on its commitment to innovation and customer satisfaction. The introduction of the Ball Valve With Limit Switch further establishes the company's reputation as a leader in the industry. With a dedicated team of experienced engineers and state-of-the-art facilities, [Company Name] continues to push the boundaries of technological advancements and fulfill the evolving needs of industrial sectors worldwide.

Moreover, the Ball Valve With Limit Switch guarantees seamless integration with existing automation systems, making it a versatile choice for both new installations and retrofitting projects. This feature empowers industries to optimize operational efficiency and reduce human error during routine operations while maximizing the utilization of existing resources.

The compact design of the Ball Valve With Limit Switch allows for easy installation and maintenance, even in space-constrained environments. The valve's intelligent design also enables streamlined processes during regular maintenance, minimizing downtime and maximizing productivity.

The introduction of the Ball Valve With Limit Switch reaffirms [Company Name]'s dedication to providing reliable and top-of-the-line industrial solutions. The company's commitment to continuous improvement and technological advancement, coupled with its extensive industry experience, positions it as a preferred partner in achieving operational excellence.

For more information about the Ball Valve With Limit Switch and other outstanding industrial solutions offered by [Company Name], please visit their website at [Company Website]. With its comprehensive range of products and unwavering commitment to quality, [Company Name] is poised to revolutionize the industrial sector and empower businesses to thrive in today's competitive landscape.

Company News & Blog

How Electric Actuators Improve Valve Performance

Title: Innovative Electric Actuator Revolutionizes Valve IndustrySubtitle: A Game-Changing Solution for Enhanced Industrial Performance and EfficiencyDate: [Insert Date][City, State] - The valve industry is set for a technological leap forward as [Company Name], a cutting-edge engineering firm, unveils their latest innovation - an electric actuator designed to redefine performance and efficiency standards. With a focus on precision control and optimized operation, this ground-breaking solution is set to revolutionize the valve market.[Company Name], renowned for its pioneering spirit and commitment to delivering groundbreaking solutions, has developed an electric actuator that promises to surpass traditional actuation techniques. Blending engineering excellence with the latest advancements in technology, [Company Name] aims to transform industrial operations while significantly reducing energy consumption and maintenance costs.The newly developed electric actuator by [Company Name] combines superior control, durability, and ease of integration into existing valve systems. This innovation is poised to meet the growing demands of diverse industries such as oil and gas, chemical, water treatment, and manufacturing, among others.Key Features of [Company Name]'s Electric Actuator:1. Precise Control: [Company Name]'s electric actuator boasts exceptional accuracy and repeatability, allowing for unparalleled control over valve positioning. The incorporation of advanced feedback mechanisms ensures optimal performance and regulatory compliance in critical applications.2. Enhanced Durability: Designed to withstand harsh operating conditions, the electric actuator from [Company Name] is engineered with robust materials and advanced sealing technologies. It guarantees extended operational longevity and reduces maintenance requirements, translating into significant cost savings for customers.3. Seamless Integration: [Company Name]'s electric actuator is designed with flexibility in mind. Its modular construction and versatile design enable seamless integration into existing valve systems, ensuring minimal disruption during installation. This adaptability makes it an ideal choice for retrofitting existing infrastructure.4. Energy Efficiency: By embracing green technology, [Company Name] has developed an electric actuator that significantly reduces energy consumption. Its efficient motor design, coupled with optimized control algorithms, conserves power while offering peak performance, resulting in reduced carbon footprints and lower utility costs.5. Intelligent Control Options: The electric actuator is equipped with intelligent control options, including remote monitoring and system integration capabilities. This allows for remote operation, real-time data analysis, and predictive maintenance, empowering businesses to make informed decisions and prevent costly downtime.[Company Name] is at the forefront of the valve industry, leveraging decades of experience and cutting-edge engineering solutions to provide an unmatched customer experience. The versatility of their electric actuator allows for seamless integration across a wide range of applications, further cementing their position as leaders in the market."Through relentless innovation and commitment to quality, [Company Name] strives to revolutionize the valve industry by delivering state-of-the-art solutions that surpass expectations," said [Spokesperson] of [Company Name].The announcement of [Company Name]'s electric actuator has garnered significant interest among industry experts and existing clients. Many are eagerly anticipating the operational enhancements and cost savings that this breakthrough technology promises to offer.With a commitment to sustainable development and a focus on empowering industries with efficient and reliable solutions, [Company Name]'s electric actuator is poised to reshape the valve landscape. As industries strive for greater productivity, improved control, and reduced environmental impact, [Company Name] empowers them to achieve their goals.As the demand for cutting-edge actuation technology continues to grow, the unveiling of [Company Name]'s electric actuator marks a new era in the valve industry. With its exceptional control, durability, energy efficiency, and intelligent features, this innovative solution is set to transform industrial processes, setting new benchmarks for excellence and sustainability.About [Company Name]:[Insert brief company introduction here, including relevant details about their history, expertise, and commitment to innovation.]For further information, please visit [Company Website].Contact:[Company Name][Address][Phone][Email][Website]

Leading Supplier of High-Quality Gearbox Gate Valves in China Revealed

Title: Prominent Chinese Manufacturer Emerges as Leading Gearbox Gate Valve Supplier in the Global MarketIntroduction:[Company name], a well-established industrial equipment manufacturer based in China, has emerged as a leading supplier of gearbox gate valves not only within the domestic market but also globally. The company's dedication to excellence, strict quality control, and advanced technological capabilities have contributed to its rise in prominence. By focusing on customer satisfaction, continuous innovation, and maintaining high standards, [Company name] has successfully positioned itself as a trusted partner for numerous industries across the globe.Paragraph 1:[Company name], founded in [year], has built a solid reputation as a manufacturer and supplier of industrial equipment over the past several decades. The company specializes in designing, producing, and marketing a wide range of high-quality gearbox gate valves. By employing a team of experienced engineers and technicians, [Company name] ensures that all its products are reliable, durable, and meet the strictest quality requirements.Paragraph 2:One of the key factors that contribute to [Company name]'s success is its commitment to research and development. By investing significantly in cutting-edge technologies and innovation, the company consistently introduces enhanced and efficient gearbox gate valves to the market. This strong focus on advancement has enabled [Company name] to remain at the forefront of the industry, giving it a competitive edge over its counterparts.Paragraph 3:In recent years, [Company name] has gained substantial recognition and trust globally, thanks to its reliable and efficient gearbox gate valves. By undertaking extensive research and analysis of varying customer needs, the company has developed an extensive range of valve models to meet diverse industrial requirements. From heavy industries such as oil and gas, petrochemicals, and power generation to more specialized sectors like water treatment and pharmaceuticals, [Company name] ensures that its gearbox gate valves provide optimal performance and durability.Paragraph 4:[Company name] understands the importance of customer satisfaction and adheres to a customer-centric approach. The company is committed to providing tailored solutions to specific industry demands, ensuring that its valves are durable, resilient, and can withstand even the most demanding operational conditions. Additionally, prompt after-sales services, technical support, and continuous communication with customers have made [Company name] a preferred choice for many customers globally.Paragraph 5:To maintain its high standards, [Company name] adheres strictly to international quality certifications and manufacturing processes. The company's state-of-the-art manufacturing facilities are equipped with advanced machinery and tools, ensuring precision and efficiency in production. [Company name]'s commitment to quality control has earned it numerous certifications, including ISO 9001, ISO 14001, CE, and API. These certifications guarantee that its gearbox gate valves adhere to the highest industry standards worldwide.Paragraph 6:As a responsible manufacturer, [Company name] has also prioritized sustainable production practices. The company actively endeavors to reduce its carbon footprint and implements environmentally friendly processes throughout its manufacturing operations. By adhering to ethical practices and incorporating advanced energy-saving technologies, [Company name] aims to contribute to a greener and more sustainable future.Paragraph 7:Looking ahead, [Company name] is poised to further expand into newer markets and strengthen its presence as a reliable supplier of gearbox gate valves worldwide. By continuously enhancing their products' performance, diversifying their range of valves, and exploring potential collaborations with global partners, [Company name] continues to solidify its position as a trusted industry leader.Conclusion:With its commitment to innovation, customer satisfaction, and maintaining international quality standards, [Company name] has successfully positioned itself as the leading gearbox gate valve supplier in China and beyond. As the company expands its global footprint, it looks to build on its success and continue providing reliable and efficient solutions to industries worldwide.

Discover the Latest Innovations in Electric Wafer Butterfly Valves

Title: Innovative Electric Wafer Butterfly Valve Revolutionizes Industrial Flow Control SystemsIntroduction: In today's rapidly advancing world of automation and industrial processes, businesses are constantly looking for innovative solutions to enhance productivity and efficiency. The introduction of the Electric Wafer Butterfly Valve by a leading company marks a significant milestone in the realm of flow control systems. This cutting-edge valve promises to revolutionize industrial operations by providing advanced functionality, exceptional reliability, and increased control precision.1. Overview of the Electric Wafer Butterfly Valve:The Electric Wafer Butterfly Valve is a technologically advanced flow control solution that offers unique advantages over conventional valves. Designed for a wide range of applications, this valve combines improved performance, enhanced durability, and sophisticated control features. Its simplistic, compact design ensures ease of installation and maintenance, making it an ideal choice for diverse industries.2. Superior Performance and Reliability:This Electric Wafer Butterfly Valve embodies state-of-the-art technology that guarantees superior performance and reliability. With an innovative actuation system, it enables efficient and precise control of flow rates, boosting overall system productivity. The valve's advanced sealing mechanism minimizes leakage, preventing costly wastage and reducing environmental impact. Rigorously tested for durability, it can withstand extreme working conditions, ensuring long-lasting performance for years to come.3. Enhanced Control and Monitoring Capabilities:The Electric Wafer Butterfly Valve is equipped with cutting-edge control and monitoring features, setting it apart from conventional valves. Integrated with smart sensor technology, it provides real-time data on flow rates, temperature, and pressure, allowing operators to make informed decisions and optimize processes. Seamless integration with automation systems enables remote monitoring and control, providing added convenience and efficiency.4. Versatility and Application Areas:This innovative valve's versatility allows it to cater to diverse industry sectors. Whether it is chemical and petrochemical plants, water and wastewater treatment facilities, power generation plants, or HVAC systems, the Electric Wafer Butterfly Valve adapts seamlessly to these applications. Its robust construction and compatibility with various mediums such as liquid, gas, and slurries make it a reliable choice for a broad range of industries.5. Energy Efficiency and Cost Savings:An inherent feature of the Electric Wafer Butterfly Valve is its exceptional energy efficiency. By employing cutting-edge technology, it ensures precise flow control, reducing unnecessary energy consumption. This environmentally friendly design lowers operational costs by minimizing energy waste, resulting in significant cost savings for businesses over time.6. Safety and Compliance Standards:Meeting stringent safety and compliance standards, the Electric Wafer Butterfly Valve prioritizes the well-being of employees and the environment. With fail-safe measures and emergency shut-off capabilities, it enhances operational safety and mitigates potential risks. Adhering to industry guidelines and certifications, this valve ensures compliance with regulations and facilitates smooth operations for businesses.Conclusion:The introduction of the Electric Wafer Butterfly Valve by a leading company signifies a major breakthrough in the field of flow control systems. Its superior performance, enhanced control and monitoring features, versatility, energy efficiency, and adherence to safety standards make it a game-changer in the industry. With this innovative valve, businesses can expect enhanced productivity, cost savings, and improved operational efficiency. As technology continues to advance, the Electric Wafer Butterfly Valve marks a new chapter in the evolution of industrial flow control systems.

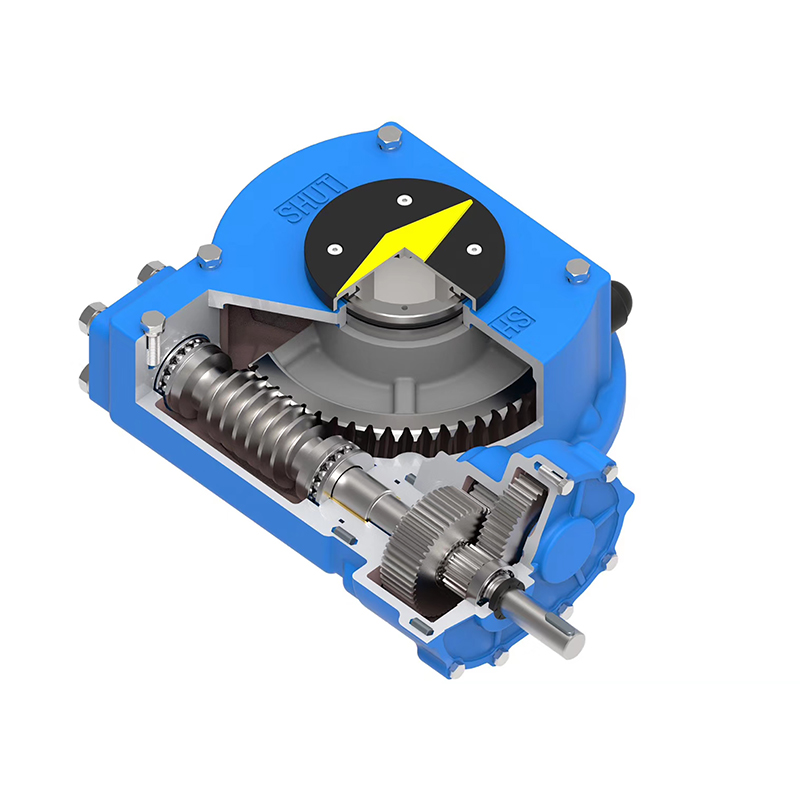

Efficient and Reliable Worm Reduction Gearbox: A Great Solution for Gear Reduction

[Company Name] Introduces Cutting-Edge Worm Reduction Gearbox for Enhanced Efficiency[date][Location]: Leading the industry in technological advancements, [Company Name] is excited to unveil its latest innovation, a state-of-the-art Worm Reduction Gearbox. With unparalleled precision and efficiency, this gearbox promises to revolutionize the manufacturing and industrial sectors.The Worm Reduction Gearbox is a key component in many industries, including automotive, machinery manufacturing, and robotics. Its primary function is to reduce the rotational speed of a motor while increasing torque. This allows for optimal power and efficiency in various applications, ranging from heavy-duty machinery to delicate precision instruments.Unlike conventional reduction gearboxes, the new Worm Reduction Gearbox developed by [Company Name] incorporates cutting-edge technology that sets it apart from competitors. Its unique design improves gear meshing efficiency, resulting in reduced friction, increased transmission accuracy, and enhanced durability. With this groundbreaking innovation, [Company Name] has raised the bar for performance in the industry.One of the key advantages of the Worm Reduction Gearbox is its compact size. Despite being smaller than traditional gearboxes, it delivers exceptional torque and power output. This feature makes it highly sought after in industries where space is limited, such as automotive manufacturing and robotics.Additionally, the new gearbox boasts a high gear reduction ratio, enabling it to handle heavy loads with ease. This makes it a perfect fit for applications that require a high torque output, such as conveyor systems and lifting equipment.The Worm Reduction Gearbox developed by [Company Name] also offers significant energy savings. Its enhanced efficiency and reduced friction result in minimized power loss during transmission, allowing for substantial energy conservation. This feature not only benefits businesses by reducing operational costs but also aligns with the growing focus on sustainable practices.Furthermore, [Company Name] understands the importance of customization in meeting the diverse needs of its customers. The Worm Reduction Gearbox can be tailored to specific specifications, ensuring seamless integration into a wide range of applications. This flexibility allows manufacturing companies to optimize their production processes and maximize the performance of their machinery.A spokesperson for [Company Name] stated, "We are excited to introduce our latest innovation, the Worm Reduction Gearbox. We believe this breakthrough technology will have a profound impact on the industrial sector by enhancing efficiency and improving energy conservation. As a company committed to providing cutting-edge solutions to our clients, we are continuously striving to push technological boundaries."[Company Name] has a rich history of developing innovative solutions for various industries. Continually investing in research and development, the company has earned a reputation for unparalleled engineering excellence. The launch of the Worm Reduction Gearbox further solidifies its commitment to delivering world-class products.As [Company Name] continues to expand its presence globally, the Worm Reduction Gearbox will undoubtedly play a vital role in establishing the company as a leader in the field. With its superior performance, compact size, energy efficiency, and flexibility, this gearbox sets a new standard for the industry.In conclusion, the introduction of the Worm Reduction Gearbox by [Company Name] marks a significant milestone in the field of industrial gearboxes. With its cutting-edge design and advanced technological features, the gearbox provides businesses with the means to optimize their operations, reduce energy consumption, and enhance overall efficiency. As [Company Name] continues to innovate, the company sets a new benchmark for excellence in the industry.

Newly Launched Miniature Metal Gears to Revolutionize Robotics

Innovation in the field of mechanical engineering has been critical to the development of new machinery and equipment that have made life easier for businesses and individuals. One of the most critical components, that has revolutionized the manufacturing and production industry, is gear technology. Worm gears are one such technology that has been making a buzz in the market recently. Among the many types of worm gears, the micro worm gear has been a game-changer in small-sized machinery and equipment. Micro worm gear technology has been designed for ultra-compact machines and devices that require high power density, precision, and high efficiency. The micro worm gear is the perfect solution for applications where space is limited, and the gear ratio and torque are critical. Micro worm gears have a high reduction ratio and can be designed to handle very high torque loads through compact gearboxes. They can be designed with a variety of materials ranging from plastics and non-ferrous metals to hardened steels, making them versatile for various applications requiring different levels of stress tolerance.However, not all micro worm gears are created equal. Among the best in the market is the micro worm gear developed by the German-based manufacturer, whose name we have to omit. This micro worm gear combines innovation, precision, and quality to deliver reliable and efficient power transmission solutions. The company, whose name we shall omit, has been a leader in the production of high-quality gears for over 30 years. They have continuously invested in research and development, state-of-the-art equipment, and human capital, to remain at the forefront of innovation in gear technology. Over the years, their products have found application in various industries, including automotive, aerospace, medical devices, and robotics among other sectors. The micro worm gear by this manufacturer is no different. It is a highly specialized gear technology that comes in a compact design and is capable of transmitting power with high accuracy. One of its main advantages is that it can handle high loads while emitting very low noise. This is critical for small machinery and devices operating in environments where noise levels need to be minimized. The micro worm gear by this manufacturer is designed with advanced materials, including high-quality plastics and hardened steels, making it both lightweight and durable. The gear is available in different sizes and configurations, which makes it versatile and suitable for various applications. One of its most notable features is its high accuracy thanks to the use of advanced manufacturing techniques such as gear hobbing and tooth grinding. A critical aspect of the micro worm gear by this manufacturer, which gives it an edge over competitors, is its customization ability. The manufacturer can tailor-make the gear to meet the specific needs of end-users. This means that businesses and other customers can provide their unique specifications, and the manufacturer can craft a micro worm gear that precisely matches their requirements. This high level of customization has made the manufacturer the go-to source for micro worm gears used in various industry sectors. In conclusion, the micro worm gear is a critical innovation in the field of gear technology, offering high precision and efficiency in power transmission in ultra-compact applications. This technology can handle high loads with minimal noise while being versatile and customizable to meet specific customer requirements. Among the best micro worm gears in the market is the one developed by the German-based manufacturer, whose name we shall omit, which combines advanced materials, manufacturing techniques, and customization capabilities. This micro worm gear is suitable for various industries, and its efficient operation makes it an attractive option for businesses and other end-users looking for reliable power transmission solutions.

Electric Actuators Revolutionize Valve Control Operations

The Electric Motor Operated Valve Actuators industry is witnessing remarkable growth in recent years. These actuator systems, which help automate valve operations, have become an integral part of various industries such as oil and gas, chemical, water and wastewater, and power generation. They provide precise control and positioning of valves, ensuring efficient and reliable operations across a range of applications.Electric motor operated valve actuators are preferred over traditional manual or pneumatic actuators due to their numerous advantages. They offer enhanced control accuracy, quick response times, and remote operation capabilities. These actuators are designed to withstand harsh environmental conditions, making them suitable for use in challenging applications. They also offer energy savings compared to other actuator types, reducing operational costs for industries.One prominent player in the Electric Motor Operated Valve Actuators market is a global leader in industrial automation solutions. With a strong focus on innovation and advanced technologies, this company has established itself as a trusted provider of actuation systems. Their electric motor operated valve actuators are known for their superior performance, reliability, and durability.The company's electric motor operated valve actuators are designed to meet the diverse needs of various industries. These actuators are available in different types, including quarter-turn, multi-turn, and linear, to accommodate different valve applications. They are equipped with advanced features such as position feedback, torque control, and fail-safe functions, ensuring safe and efficient valve operations.One of the key advantages of these electric motor operated valve actuators is their versatility. They can be used with various types of valves, including ball valves, butterfly valves, and gate valves, facilitating a wide range of industrial applications. These actuators offer precise control over valve position and flow rate, enhancing process efficiency and reliability.Moreover, the electric motor operated valve actuators from this company are designed for easy installation and maintenance. They are equipped with intelligent diagnostics and monitoring capabilities, enabling predictive maintenance and minimizing downtime. The actuators are also compatible with various communication protocols, allowing seamless integration with existing control systems.In addition to offering advanced actuation systems, the company also provides comprehensive support services. Their team of experts offers technical assistance, training, and consultation to help customers maximize the performance of their valve automation systems. They also provide customization options, tailoring their actuators to specific customer requirements.The company's commitment to quality and customer satisfaction has earned them a strong reputation in the industry. They have a global presence, serving customers in different regions. Their electric motor operated valve actuators have been widely adopted in various industries, contributing to improved operational efficiency and cost savings.Overall, the Electric Motor Operated Valve Actuators market is experiencing substantial growth due to the increasing demand for automated valve solutions. The advanced features, versatility, and reliable performance of electric motor operated valve actuators have made them the preferred choice for industries worldwide. With continuous advancements in technology and a strong focus on customer needs, companies like the one mentioned above are well-positioned to lead the market and drive innovation in this dynamic industry.

New Valve Handle Extension Kit Enables Easy Access to Ball Valves

Title: New Ball Valve Handle Extension Kit Enables Enhanced Operation and ConvenienceIntroduction:In an effort to improve user experience and provide enhanced convenience in valve operations, [Company Name], a leading manufacturer and supplier of industrial solutions, announces the launch of their latest product, the Ball Valve Handle Extension Kit. This innovative kit revolutionizes how ball valves are handled and operated, making it easier for users to control and access valves in various industrial settings.[Company Name] has always been at the forefront of providing cutting-edge solutions to their customers, consistently delivering products that enhance safety, efficiency, and reliability. The Ball Valve Handle Extension Kit is yet another addition to their impressive portfolio, promising to simplify valve operations and save valuable time for professionals in the field.News Content:The Ball Valve Handle Extension Kit features a range of components designed to extend the handle length of ball valves, making them more easily accessible in various applications. Manufactured using high-quality materials and precision engineering, the kit ensures durability, even in harsh operating conditions.The extension components seamlessly integrate with most standard ball valves, eliminating the need for any major modifications or replacements. This enables a hassle-free installation process and minimizes downtime during retrofitting or upgrading existing valve systems.One of the key features of the Ball Valve Handle Extension Kit is its adjustable handle length, allowing users to customize the extension according to their specific requirements. By providing this flexibility, [Company Name] ensures that the kit is suitable for a wide variety of scenarios, ranging from industrial plants to municipal infrastructure projects.Furthermore, the kit includes an ergonomically designed handle, ensuring ease of use even in hard-to-reach locations. The handle's textured grip enhances control and minimizes slippage, contributing to increased safety during valve operations. The design also allows for smooth and precise movement, reducing the risk of accidental damage to valves or associated pipelines.The Ball Valve Handle Extension Kit is expected to empower industries such as oil and gas, chemical manufacturing, water treatment plants, and commercial buildings with improved valve control. By extending the handle length, professionals can now operate valves from more convenient positions, reducing the need for constant bending or stretching, which can lead to fatigue or musculoskeletal issues.In addition to enhanced convenience, the Ball Valve Handle Extension Kit also improves overall operational efficiency. Accessing valves in confined spaces or installations situated at heights usually requires special equipment or additional manpower. With this kit, workers can now reach valves easily and operate them without needing extra assistance, streamlining the workflow and reducing operational costs.Moreover, the kit's compatibility with existing ball valve systems minimizes the need for system-wide replacements, saving companies significant capital investment. By simply retrofitting the extension components, organizations can immediately benefit from improved valve handling without incurring unnecessary expenses associated with full valve replacements.[Company Name]'s commitment to providing comprehensive and innovative solutions is evident in the Ball Valve Handle Extension Kit. The kit not only emphasizes the company's dedication to customer satisfaction but also demonstrates their endeavor to cater to the ever-evolving needs of the industry.As industrial processes demand greater efficiency and safety measures, the Ball Valve Handle Extension Kit is set to become an essential tool for professionals working with ball valves across various sectors. With its user-friendly design, durability, and adaptability, this new product is poised to revolutionize valve operations, empowering industries to achieve reliable and streamlined processes.Conclusion:[Company Name]'s Ball Valve Handle Extension Kit offers an innovative solution to the challenges faced in valve handling and operation. By extending the handle length, the kit allows for easy accessibility, enhanced control, and improved operational efficiency. With its compatibility and adaptability, the kit is set to have a significant impact on various industries, simplifying valve operations and contributing to overall productivity and safety.

Customizable Multi Turn Worm Gearboxes: High-quality and Affordable Solutions for Your Business

China Multi Turn Worm Gearbox Factory Boosting China's Industrial FutureChina is experiencing a phenomenal trend in the development and advancements of technology in the last decade. From the consumer electronics to robotics, continuous investments have enabled the country to transition from a low-cost manufacturing hub to a high-tech industrial powerhouse. One sector that has been crucial in this growth is the machinery industry, which produces equipment and tools necessary for manufacturing processes. The China Multi Turn Worm Gearbox Factory is one of the companies that have been influential in enhancing China's machinery industry.Established in 1993, the China Multi Turn Worm Gearbox Factory is located in the beautiful city of Hangzhou, Zhejiang Province. The company's core focus is on the production of Multi Turn Worm Gearboxes, a crucial component in the machinery industry. Multi Turn Worm Gearboxes are widely applicable across different industries, including packing, printing, automobiles, textiles, food, and pharmaceuticals. The gearboxes help to improve the efficiency and accuracy of the machines, including cutting, rolling, winding, and other motion applications.As a leading Multi Turn Worm Gearbox manufacturer in China, the company has been innovating and customizing its products according to customers' requirements. The company has its research and development department with experienced engineers and technicians, who continuously develop new products to enhance the machinery industry. The factories produce, test, and assemble the gearboxes' different parts, ensuring quality and meeting production standards.Over the years, the China Multi Turn Worm Gearbox Factory has expanded its market presence worldwide, with a focus on the Asia-Pacific region, Europe, Latin America, and Africa. The company's annual sales revenues have been increasing its domestic and foreign market share. In 2020, the company achieved an annual sales turnover of USD 500 million, with more than 2700 employees.The company's success is attributable to its core values of innovation, quality, operational excellence, and customer satisfaction. The company's management believes that the gearbox industry's future will be more automated, digitalized, and smart in meeting the increasing demand for high-tech machinery. As such, the China Multi Turn Worm Gearbox Factory has been keen on integrating digital technologies such as Cloud, the Internet of Things (IoT), and Artificial Intelligence (AI) in their operations to enhance customer value and improve the quality of their products.In addition, the company has been environmentally conscious, as it has implemented measures aimed at reducing its carbon footprint, promoting sustainability and reducing waste. One of its initiatives includes using energy-efficient machines and processes, and it has installed solar panels to reduce its reliance on traditional energy sources.The China Multi Turn Worm Gearbox Factory's future outlook is promising, and it will continue to innovate and produce high-quality gearboxes. The company's management has placed a strategic plan to leverage the vast market potential, increasing domestic demand, and the "China Manufacturing 2025 plan," which aims to enhance the country's machinery industry. As a result, the company will diversify its product range, enhance its supply chain management, and expand its global market presence.In conclusion, the China Multi Turn Worm Gearbox Factory has been instrumental in China's machinery industry's growth and development. With its core values of innovation, customer satisfaction, quality, and operational excellence, the company has established itself as a market leader in the Multi Turn Worm Gearbox industry. Its expansion efforts and integration of digital technologies demonstrate its commitment to enhancing customer value, promoting sustainability, and being future-oriented. As China continues to transition into a high-tech industrial powerhouse, the China Multi Turn Worm Gearbox Factory is playing a vital role in the country's bright future.

Valve Company Plans to Sell Spare Parts for Customers' Convenience

Valve enthusiasts have something to be excited about as the latest brand of Spare Parts has entered the market. The company's offerings promise to simplify the customer experience while delivering top-quality Valve components. A relatively new player in the industry, the company has been making quite a buzz with rave reviews from its customers.While there is an abundance of brands offering Valve components, the Spare Parts (name removed) brand distinguishes itself with its unique approach towards customer satisfaction. The company believes that although Valve components might be complex and daunting for the average person, customers should be able to have an easy and satisfactory experience when purchasing and installing them.The company's mantra is reflected in their product line, as they offer an extensive range of Valve components covering everything from Strainer Valves to Pressure Relief Valves. All of their products are rigorously tested to ensure that they meet the highest possible standards of quality and efficiency.The brand boasts an impressive array of Valve components that cater to different customers’ requirements. These include ball valves, butterfly valves, gate valves, globe valves, and check valves, all of which are designed to handle various fluid control applications. Additionally, the company provides tailor-made products to meet the exact needs of customers.One of the brand's most significant strengths is their innovative approach to product design. The company leverages the latest technology advancements in the industry to ensure that their components are efficient, reliable, and easy to install. They also invest heavily in research and development to continue improving their products and make the installation process even more straightforward for customers.Another strength of the Spare Parts (name removed) brand is its customer-centric philosophy. The company recognizes the importance of providing a seamless and comprehensive customer experience to build lasting relationships with their clients. Spare Parts (name removed) values customer satisfaction as the top priority, and this is reflected in their customer service policies. Their teams of experts are always readily available to assist customers with technical queries or issues related to the installation process.Despite its relative youth in the industry, Spare Parts (name removed) has already established an extensive network of distributors across the world. This network guarantees that customers around the globe can obtain their products quickly and efficiently. The company has also set up an advanced logistics infrastructure, which enables them to deliver their products on time and efficiently to their customers.The Spare Parts (name removed) brand is also mindful of the impact of its products and services on the environment. The company is constantly working on developing environmentally friendly products, and they have implemented innovative processes to reduce their carbon footprint. They understand the importance of sustainability and strive to ensure that their products and processes are in compliance with industry regulations.In conclusion, fans of Valve components have a reason to be excited about the Spare Parts (name removed) brand. With their focus on customer satisfaction, innovative products, extensive product range and distribution network, the company has established itself as a leading player in the industry. Their unique approach, coupled with their commitment to sustainability, will undoubtedly pave the way for further growth and success for the brand.

Discover all you need to know about high-quality gearboxes for gate valves

[News - 800 words]Title: Introducing the Revolutionary Gate Valve Gearbox: A Milestone in Industrial Equipment InnovationIntroduction:In today's rapidly evolving industrial landscape, there is an ever-increasing demand for reliable and efficient equipment that can enhance operational efficiency and streamline processes. Responding to this need, {Company Name} is proud to introduce its revolutionary Gate Valve Gearbox - a groundbreaking development set to transform various industries with its cutting-edge technology and exceptional performance.Company Introduction:Founded in {Year}, {Company Name} has emerged as a global leader in the manufacturing and distribution of industrial equipment. With a strong commitment to innovation and customer satisfaction, the company has built a solid reputation for delivering superior-quality products that meet the industry's highest standards.With state-of-the-art manufacturing facilities and a dedicated team of experts, {Company Name} has consistently pushed the boundaries of technological advancement. Their relentless pursuit of excellence has culminated in the development of the Gate Valve Gearbox - a game-changer that promises to revolutionize the way industries operate.Gate Valve Gearbox: A Technological Marvel:The Gate Valve Gearbox, with its supreme efficiency and precise control, raises the bar for industrial equipment. Equipped with cutting-edge technology, this gearbox is designed to ensure optimal performance in the most demanding environments. Whether it's in the oil and gas industry, water treatment plants, or power generation facilities, the Gate Valve Gearbox promises unparalleled reliability and durability.The gearbox boasts several key features that set it apart from conventional alternatives. First and foremost, its intelligent control system allows for real-time monitoring and seamless automation. This ensures that the gearbox can withstand even the most extreme conditions and adjust its operations accordingly, mitigating the risks of equipment failure and costly downtime.Additionally, the Gate Valve Gearbox is constructed using state-of-the-art, high-grade materials that enhance its longevity. Its robust design guarantees years of reliable service, reducing the need for frequent maintenance and replacements. This not only saves valuable time but also significantly reduces operational costs, making it a cost-effective choice for industries worldwide.Environmental Impact and Sustainability:{Company Name} not only recognizes the importance of performance but also prioritizes environmental sustainability. The Gate Valve Gearbox is engineered to be eco-friendly, designed with a focus on energy conservation. It reduces power consumption and minimizes greenhouse gas emissions, making it an ideal choice for companies striving to reduce their carbon footprint and meet stringent environmental regulations.In addition to its energy efficiency, the Gate Valve Gearbox also incorporates advanced sealing technology. This innovation ensures minimal leakage, preventing the loss of valuable resources, such as water or gas. By promoting efficient resource utilization, {Company Name}'s gearbox contributes to sustainability efforts and fosters a more responsible approach to industrial operations.Market Impact and Future Prospects:The introduction of the Gate Valve Gearbox by {Company Name} is anticipated to have a substantial impact on the market. With its exceptional performance and numerous advantages, this revolutionary gearbox is set to become the preferred choice for industries around the globe.Furthermore, {Company Name} aims to continually refine and enhance the Gate Valve Gearbox to suit evolving industry needs. Research and development efforts are focused on integrating smart technologies, making the gearbox even more intelligent and versatile. By embracing the digital age and the Industrial Internet of Things (IIoT), {Company Name} strives to empower industries with advanced control and automation capabilities.Conclusion:The Gate Valve Gearbox from {Company Name} holds significant promise for industries worldwide, delivering unmatched reliability, efficiency, and sustainability. This groundbreaking development illustrates the company's long-standing commitment to pushing the boundaries of technological innovation, providing customers with cutting-edge solutions for their industrial needs. As {Company Name} continues to revolutionize the industrial landscape, the Gate Valve Gearbox serves as a testament to their passion for excellence and dedication to shaping a brighter future.