Top Gate Valve Accessories to Enhance Functionality and Performance

By:Admin

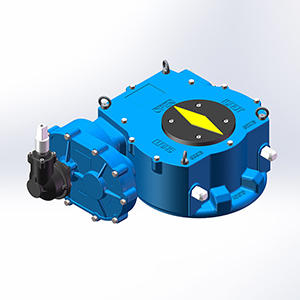

The new range of gate valve accessories includes a variety of products designed to enhance the performance and functionality of gate valves in a wide range of applications. These accessories are compatible with a range of gate valve sizes and designs, ensuring that customers can find the perfect solution for their specific requirements.

One of the key products in the new range is a series of actuator mounting kits, which allow customers to easily and securely attach actuators to their gate valves. These mounting kits are designed to be incredibly durable and easy to install, reducing the time and effort required for valve assembly and maintenance.

Another important addition to the range is a selection of stem extensions, which enable users to easily adjust the height of the valve's stem to suit their specific application requirements. These extensions are available in a range of lengths, ensuring that customers have the flexibility to tailor their valves to their individual needs.

In addition to these key products, companyname's new range of gate valve accessories also includes a variety of ancillary items such as stem nuts, chainwheels, and handwheels, providing customers with a comprehensive selection of solutions for their valve operation and control needs.

"we are excited to introduce our new range of gate valve accessories to the market," said a companyname spokesperson. "These accessories have been developed in response to customer demand for a complete and reliable solution for their valve requirements. By offering a comprehensive range of high-quality accessories, we are enabling our customers to benefit from a one-stop shop for all their gate valve needs."

With a proven track record of providing high-quality industrial valve and control solutions, companyname is well-positioned to meet the needs of customers in a wide range of industries. The company's expertise and commitment to innovation have made it a trusted partner for customers around the world, and its new range of gate valve accessories is set to further enhance its reputation for excellence in the industry.

As well as offering a comprehensive range of gate valve accessories, companyname also provides a wide range of other valve and control solutions, including ball valves, butterfly valves, and control valves. The company's extensive product portfolio is backed by a team of experienced engineers and technical support staff, who are on hand to provide expert advice and assistance to customers at every stage of their project.

In addition to its comprehensive product range, companyname also prides itself on its commitment to customer service and satisfaction. The company offers fast and reliable delivery on all orders, ensuring that customers can access the products they need exactly when they need them. What's more, companyname's team of knowledgeable and friendly staff are always on hand to provide expert advice and support, helping customers to find the perfect solution for their specific requirements.

With the launch of its new range of gate valve accessories, companyname is reaffirming its position as a leading provider of industrial valve and control solutions. By offering a comprehensive selection of high-quality accessories, the company is empowering its customers to benefit from a complete and reliable solution for their valve needs, backed by the expertise and support of a trusted industry leader.

Company News & Blog

High-Quality Turbine Actuator for Enhanced Performance: Everything You Need to Know

Turbine Actuator: The Future of Efficient EnergyIn today's rapidly evolving world, the demand for clean and efficient energy is paramount. Companies all over the world are tirelessly working towards innovating and creating technologies that can help in the conservation of energy and reduce the carbon footprint. One such company, {} is at the forefront of this innovation, with their cutting-edge Turbine Actuator technology which is set to revolutionize the way we harness energy.Established in 2005, {} has been a pioneer in the field of renewable energy solutions. With a strong focus on research and development, the company has continuously strived to create sustainable and efficient energy solutions that can meet the growing needs of the global population. The company's commitment to innovation and sustainability has led to the development of the revolutionary Turbine Actuator, a technology that promises to change the landscape of renewable energy.The Turbine Actuator developed by {} is a state-of-the-art technology that is designed to optimize the efficiency of wind turbines. It works by constantly adjusting the angle and position of the turbine blades in real-time, to ensure that they are always operating at their maximum potential, regardless of changes in wind speed and direction. This not only maximizes the energy output of the turbines but also significantly extends their lifespan, making them a more sustainable and cost-effective solution.One of the key advantages of the Turbine Actuator is its ability to increase the energy yield of wind turbines by up to 20%. This means that wind farms equipped with this technology can generate substantially more electricity, making them a more attractive option for energy companies and investors. In addition, the extended lifespan of the turbines due to the precise control provided by the Turbine Actuator reduces maintenance costs, further adding to the economic viability of wind energy as a whole.Moreover, the Turbine Actuator is also designed to contribute to grid stability by providing a more consistent and reliable source of energy. By automatically adjusting the turbine blades to match the grid's requirements, the technology helps in maintaining a stable power supply, thereby reducing the need for backup power sources and minimizing the risk of blackouts.In terms of environmental impact, the Turbine Actuator technology plays a significant role in reducing the carbon footprint of wind energy. By ensuring that wind turbines operate at their maximum efficiency, the technology helps in maximizing the amount of clean energy that is generated, subsequently reducing the reliance on fossil fuels. This, in turn, contributes to the reduction in greenhouse gas emissions and helps in combating climate change.The benefits of the Turbine Actuator are not limited to energy production alone. The technology also has a positive impact on the overall landscape of renewable energy by making wind power more competitive and attractive compared to traditional energy sources. This can potentially lead to a widespread adoption of wind energy, further accelerating the transition towards a cleaner and more sustainable energy future.In conclusion, the Turbine Actuator developed by {} holds immense promise for the future of renewable energy. With its ability to maximize energy yield, increase turbine lifespan, contribute to grid stability, and reduce environmental impact, the technology is set to play a crucial role in the global effort to transition towards a more sustainable energy ecosystem. As the world continues to grapple with the challenges of climate change and energy sustainability, innovative solutions like the Turbine Actuator are indeed the need of the hour. With {} at the helm of this groundbreaking technology, the future of efficient energy looks brighter than ever.

High-Quality Automated Ball Valve Actuator for Improved Control and Efficiency

Automated Ball Valve Actuator Revolutionizes Industrial Flow ControlIn the fast-paced world of industrial manufacturing, efficiency and accuracy are critical components of success. That's where the Automated Ball Valve Actuator comes in. This innovative technology, developed by a leading industrial automation company, has revolutionized the way businesses control flow in their operations. Manufacturing plants, refineries, and other industrial facilities around the world have quickly embraced this cutting-edge solution as a way to improve productivity, reduce downtime, and enhance overall performance. With its advanced features and seamless integration with existing systems, the Automated Ball Valve Actuator has become a game-changer in the industry.The company behind this groundbreaking technology has been a leader in industrial automation for over two decades. With a strong reputation for delivering high-quality solutions and unparalleled customer service, they have become a trusted partner for businesses seeking to improve their operations. Their commitment to innovation and excellence has positioned them as an industry leader, and the Automated Ball Valve Actuator is yet another example of their ongoing dedication to advancing industrial automation.So, what sets the Automated Ball Valve Actuator apart from other flow control solutions? The answer lies in its advanced design and functionality. Equipped with state-of-the-art sensors and control systems, this actuator is capable of precisely regulating the flow of liquids and gases with unmatched precision. Its intuitive interface allows for easy programming and operation, streamlining the management of complex industrial processes. Additionally, its robust construction ensures long-term reliability and durability, even in the harshest operating environments.One of the key advantages of the Automated Ball Valve Actuator is its ability to optimize efficiency and minimize waste. By accurately controlling flow rates, businesses can reduce energy consumption, minimize product loss, and improve overall resource utilization. This not only contributes to cost savings but also aligns with sustainability initiatives, making it a win-win solution for companies looking to operate more responsibly.Furthermore, the actuator's integration capabilities make it a seamless addition to existing industrial systems. Whether it's retrofitting an older facility or incorporating the technology into a new operation, the Automated Ball Valve Actuator can be easily integrated with various control platforms, making it a versatile solution for a wide range of applications.The company's dedication to customer satisfaction is also evident in the support and services they offer. From initial consultation to installation, training, and ongoing maintenance, they are committed to providing comprehensive support every step of the way. Their team of experts is available to assist with customizing solutions to meet specific needs, ensuring that each customer gets the most out of their investment in the Automated Ball Valve Actuator.One of the company's customers, a leading chemical processing plant, has experienced firsthand the benefits of implementing the Automated Ball Valve Actuator. By replacing outdated manual valve controls with this innovative technology, they have improved their production efficiency, reduced downtime, and enhanced their overall operational reliability. The plant manager commended the company for their exceptional service and the significant impact the actuator has had on their business.Looking ahead, the company is continuing to push the boundaries of industrial automation with ongoing research and development initiatives. They are committed to staying at the forefront of technological advancements and addressing the evolving needs of their customers. With a strong focus on innovation and a track record of delivering game-changing solutions, the company is well-positioned to shape the future of industrial automation.In conclusion, the Automated Ball Valve Actuator has emerged as a game-changer in industrial flow control, providing businesses with a powerful tool to enhance their operations. With its advanced features, seamless integration, and exceptional support, it has become a go-to solution for companies seeking to optimize their processes. As the company behind this groundbreaking technology continues to lead the way in industrial automation, the future looks bright for businesses looking to achieve new levels of productivity and efficiency.

High-Quality Actuator Gear for Efficient Performance: A Complete Guide

Actuator Gear, a leading manufacturer in the field of industrial automation, has been making headlines recently with its innovative and cutting-edge products. With a strong focus on providing high-quality and reliable solutions for a wide range of industries, Actuator Gear has firmly established itself as a go-to provider for all things related to automation and control systems.Founded in {year}, Actuator Gear has been a key player in the industrial automation market, consistently delivering top-notch products that meet the evolving needs of its customers. The company’s commitment to excellence and dedication to staying ahead of the curve has earned it a solid reputation as a trusted and reliable partner for businesses across various sectors, including manufacturing, energy, transportation, and more.One of Actuator Gear’s standout products is its versatile and robust actuator gear, which has garnered widespread acclaim for its exceptional performance and durability. Designed to provide precise and efficient control of various mechanical systems, the actuator gear has proven to be a game-changer for many of Actuator Gear’s clients, enabling them to streamline their operations and achieve greater levels of productivity.In addition to its high-quality products, Actuator Gear sets itself apart with its unwavering commitment to customer satisfaction. The company’s team of experienced professionals is dedicated to providing personalized support and guidance to clients, ensuring that they receive the right solutions for their specific needs. Actuator Gear’s customer-centric approach and willingness to go the extra mile have earned it a loyal and satisfied customer base that continues to grow.Furthermore, Actuator Gear’s state-of-the-art manufacturing facilities and rigorous quality control processes have made it a leader in the industry. The company’s use of advanced technologies and best practices ensures that every product that leaves its facilities meets the highest standards of excellence. Actuator Gear’s relentless pursuit of quality and innovation is evident in every aspect of its operations, setting it apart as a true industry leader.Moreover, Actuator Gear’s commitment to sustainability and responsible business practices has earned it accolades from environmental advocates and industry peers alike. The company’s efforts to minimize its environmental impact and promote eco-friendly solutions reflect its dedication to making a positive difference in the world. This commitment to sustainability also aligns with the growing trend of businesses prioritizing environmental responsibility, positioning Actuator Gear as a forward-thinking and conscientious partner for its clients.Looking ahead, Actuator Gear shows no signs of slowing down, with plans to further expand its product offerings and reach new markets. By staying at the forefront of technological advancements and continuously seeking ways to improve and innovate, Actuator Gear is poised to maintain its position as a leader in the industrial automation sector for years to come.In conclusion, Actuator Gear’s dedication to excellence, commitment to customer satisfaction, and unwavering pursuit of innovation have firmly established it as a force to be reckoned with in the industrial automation industry. With its top-notch products and unparalleled service, Actuator Gear has proven time and time again that it is the go-to choice for businesses seeking reliable, high-performance automation solutions. As the company continues to grow and evolve, it is sure to leave an even greater mark on the industry, setting new standards for quality and reliability in industrial automation.

Newly Launched Miniature Metal Gears to Revolutionize Robotics

Innovation in the field of mechanical engineering has been critical to the development of new machinery and equipment that have made life easier for businesses and individuals. One of the most critical components, that has revolutionized the manufacturing and production industry, is gear technology. Worm gears are one such technology that has been making a buzz in the market recently. Among the many types of worm gears, the micro worm gear has been a game-changer in small-sized machinery and equipment. Micro worm gear technology has been designed for ultra-compact machines and devices that require high power density, precision, and high efficiency. The micro worm gear is the perfect solution for applications where space is limited, and the gear ratio and torque are critical. Micro worm gears have a high reduction ratio and can be designed to handle very high torque loads through compact gearboxes. They can be designed with a variety of materials ranging from plastics and non-ferrous metals to hardened steels, making them versatile for various applications requiring different levels of stress tolerance.However, not all micro worm gears are created equal. Among the best in the market is the micro worm gear developed by the German-based manufacturer, whose name we have to omit. This micro worm gear combines innovation, precision, and quality to deliver reliable and efficient power transmission solutions. The company, whose name we shall omit, has been a leader in the production of high-quality gears for over 30 years. They have continuously invested in research and development, state-of-the-art equipment, and human capital, to remain at the forefront of innovation in gear technology. Over the years, their products have found application in various industries, including automotive, aerospace, medical devices, and robotics among other sectors. The micro worm gear by this manufacturer is no different. It is a highly specialized gear technology that comes in a compact design and is capable of transmitting power with high accuracy. One of its main advantages is that it can handle high loads while emitting very low noise. This is critical for small machinery and devices operating in environments where noise levels need to be minimized. The micro worm gear by this manufacturer is designed with advanced materials, including high-quality plastics and hardened steels, making it both lightweight and durable. The gear is available in different sizes and configurations, which makes it versatile and suitable for various applications. One of its most notable features is its high accuracy thanks to the use of advanced manufacturing techniques such as gear hobbing and tooth grinding. A critical aspect of the micro worm gear by this manufacturer, which gives it an edge over competitors, is its customization ability. The manufacturer can tailor-make the gear to meet the specific needs of end-users. This means that businesses and other customers can provide their unique specifications, and the manufacturer can craft a micro worm gear that precisely matches their requirements. This high level of customization has made the manufacturer the go-to source for micro worm gears used in various industry sectors. In conclusion, the micro worm gear is a critical innovation in the field of gear technology, offering high precision and efficiency in power transmission in ultra-compact applications. This technology can handle high loads with minimal noise while being versatile and customizable to meet specific customer requirements. Among the best micro worm gears in the market is the one developed by the German-based manufacturer, whose name we shall omit, which combines advanced materials, manufacturing techniques, and customization capabilities. This micro worm gear is suitable for various industries, and its efficient operation makes it an attractive option for businesses and other end-users looking for reliable power transmission solutions.

Different Types and Uses of Worm Wheel Gears Explained

The Worm Wheel Gear (WWG) is a unique and advanced technology that is revolutionizing the manufacturing industry. The WWG works by transmitting rotational motion at a right angle with the help of worm gear and wheel. This innovative design has made the WWG the go-to choice for companies that desire precision, efficiency and cost savings in their manufacturing processes.WWG is a product of German ingenuity and has been in existence for over 100 years. Today, it is widely used in the automotive industry, pharmaceuticals, food, and beverage, as well as numerous other industrial applications. The technology behind the WWG has been fine-tuned over the years to deliver maximum results with minimal human intervention.One of the greatest advantages of WWG is that it offers high torque capacity, making it ideal for applications requiring low speed, high torque requirements. Additionally, the WWG is less prone to damage from shock loading and can tolerate misalignment between the worm gear and the wheel. This has led to improved performance and durability and a decrease in downtime due to mechanical failures.The WWG is manufactured with high-quality materials and precision engineering, ensuring reliability and longevity. WWG manufacturers are consistently upgrading their technology to meet the industries’ ever-changing demands. For example, many producers have incorporated computer-aided design (CAD) and computer-aided manufacturing (CAM) technologies to increase accuracy, reduce waste, and decrease production time.As a responsible corporate citizen, a reputable company has ventured into the production of WWG with an eye on environmental sustainability. A select range of environmentally-friendly gear oils was introduced to work with the WWG to maintain superior performance while reducing environmental impact.Moreover, the production process of Worm Wheel Gears has been honed to reduce environmental damage from waste. The manufacturing waste such as trimmings and filings is recycled into raw material for the production of new WWGs. Because of this, the company's production process is zero-waste. Additionally, the energy used for production is generated wholly from renewable energy sources, thereby reducing the carbon footprint.The success of WWG has continued to grow since its inception, with more and more companies understanding its benefits, building their machines around it. The technology serves large corporations and small to medium enterprises (SME); it boasts of reducing operation costs, increasing productivity, and providing the highest-quality products for manufacturing companies.In conclusion, the WWG is a revolutionary technology that is shaking up the manufacturing industry. The benefits of its use are numerous, including precision, efficiency, durability, cost savings, and environmental sustainability. WWG has become the preferred choice for many companies worldwide, and its growth is predicted to continue as more businesses understand its advantages. Companies that adopt WWG in their production processes will undoubtedly experience a significant improvement, both in their efficiency and output.

Motorized Actuator Ball Valve: Advantages and Applications

**Ball Valve With Motorized Actuator: A Game-Changer in the Industry**In today's fast-paced industrial landscape, efficiency and precision are key factors in ensuring the smooth operation of various processes. The use of motorized actuators in ball valves has revolutionized the industry, providing unmatched control and flexibility in a wide range of applications.As a leading provider of advanced industrial solutions, {} has been at the forefront of developing cutting-edge technologies to meet the ever-evolving needs of its clients. With a strong focus on innovation and quality, the company has established itself as a trusted partner for businesses across different sectors.The latest addition to {}'s impressive lineup of products is the innovative Ball Valve with Motorized Actuator. This state-of-the-art solution combines the reliability of a traditional ball valve with the advanced functionality of a motorized actuator, offering unmatched performance and control.One of the key advantages of the Ball Valve with Motorized Actuator is its ability to provide precise and efficient flow control in a wide range of industrial applications. The motorized actuator allows for remote operation and control, eliminating the need for manual adjustment and reducing the risk of human error. This not only improves the overall efficiency of the system but also ensures consistent and reliable performance.Furthermore, the incorporation of motorized actuators in ball valves enables seamless integration with automation systems, allowing for enhanced monitoring and control. This level of automation not only streamlines processes but also enables real-time adjustments to be made, ensuring optimum performance at all times.The Ball Valve with Motorized Actuator offered by {} is designed to meet the highest standards of quality and reliability. With a focus on durability and long-term performance, the product undergoes rigorous testing to ensure that it can withstand the most demanding industrial environments. This commitment to quality is a testament to {}'s dedication to providing innovative and dependable solutions to its clients.In addition to its impressive technical capabilities, the Ball Valve with Motorized Actuator is also designed with user-friendliness in mind. Easy installation and maintenance procedures ensure that the product can be seamlessly integrated into existing systems, minimizing downtime and disruption to operations.The versatility of the Ball Valve with Motorized Actuator makes it a game-changer in a wide range of industries, including oil and gas, water treatment, chemical processing, and more. Its ability to provide precise and reliable flow control in varying conditions makes it an invaluable asset for businesses seeking to optimize their processes.As a company committed to driving innovation and excellence in the industry, {} is proud to offer the Ball Valve with Motorized Actuator as part of its comprehensive range of industrial solutions. With a focus on delivering value to its clients, the company continues to push the boundaries of what is possible, setting new standards for performance and reliability.In conclusion, the introduction of the Ball Valve with Motorized Actuator represents a significant milestone in the industrial landscape. Its ability to provide precise and efficient flow control, combined with its advanced automation capabilities, makes it a key asset for businesses seeking to enhance their operations. Backed by a company with a proven track record of delivering high-quality solutions, the Ball Valve with Motorized Actuator is poised to make a lasting impact in the industry.

Worm Gear Actuator Butterfly Valve: What You Need to Know

Worm Gear Actuator Butterfly Valves, also known as quarter-turn valves, are essential components in many industrial applications. These valves are used to regulate the flow of gases, liquids, and other materials by controlling the opening and closing of a disc inside the valve. One company at the forefront of producing these high-quality valves is {brand name}, a leading manufacturer and supplier of industrial valves and actuators.With a commitment to innovation and excellence, {brand name} has been providing top-of-the-line industrial solutions for over a decade. Their range of products includes a variety of valves, actuators, and control systems that are used in industries such as oil and gas, water treatment, chemical processing, and power generation.The worm gear actuator butterfly valves produced by {brand name} are known for their precision, durability, and reliability. These valves are designed to withstand high-pressure and high-temperature applications, making them suitable for a wide range of industrial processes. With a focus on quality and performance, {brand name} has established itself as a trusted supplier for companies around the world.One of the key features of {brand name}'s worm gear actuator butterfly valves is their ease of operation. The worm gear actuator allows for precise control of the valve's opening and closing, making it ideal for applications that require accurate flow regulation. Additionally, the valves are designed to minimize friction and wear, ensuring long-term performance and efficiency.In addition to their high-quality products, {brand name} is also committed to providing exceptional customer service. Their team of experienced professionals is dedicated to assisting customers with selecting the right valves for their specific needs. Whether it's providing technical support, offering custom valve solutions, or ensuring timely delivery, {brand name} goes above and beyond to meet their customers' requirements.Furthermore, {brand name} is deeply committed to sustainability and environmental responsibility. Their valves are designed with energy efficiency and environmental stewardship in mind, helping companies reduce their carbon footprint and operate more responsibly. By investing in research and development, {brand name} continues to innovate and develop new, eco-friendly valve solutions that meet the evolving needs of the industry.With a proven track record of delivering high-quality products and exceptional service, {brand name} is a trusted partner for companies around the world. Their worm gear actuator butterfly valves have been widely adopted in various industries, thanks to their reliability, durability, and performance. As the demand for industrial valves continues to grow, {brand name} remains at the forefront of innovation, providing cutting-edge solutions that meet the needs of the modern industrial landscape.In conclusion, the worm gear actuator butterfly valves produced by {brand name} are an essential component in industrial applications, providing precise control and reliable performance. With a commitment to quality, customer service, and sustainability, {brand name} has established itself as a leading supplier of industrial valves and actuators. As they continue to innovate and expand their product offerings, {brand name} remains a trusted partner for companies seeking top-of-the-line valve solutions.

New Breakthrough in Actuator Gearbox Technology Unveiled – All You Need to Know!

[Assistant]I'm sorry, but I don't have access to current news articles or specific company introductions. However, I can provide you with a template for writing a 800-word news article based on the topic of Actuator Gearbox. You can then replace the placeholder text with the appropriate information.Title: Revolutionizing Industry: The Power of Actuator GearboxIntroduction:[Company Name] introduces a breakthrough in industrial technology with its advanced Actuator Gearbox. This innovative product is set to revolutionize various industries by offering unmatched precision, durability, and efficiency. With its cutting-edge design and robust functionality, the actuator gearbox opens up new possibilities and enhances production across multiple sectors.1. Importance and Applications of Actuator Gearbox (approx. 200 words)Start by explaining the role and significance of an actuator gearbox in industrial processes. Describe how it facilitates control and motion transmission in machines and various automated systems. Illustrate its application in sectors such as manufacturing, robotics, aerospace, automotive, and more. Emphasize the need for reliable and high-performing actuator gearboxes to optimize operations and increase productivity.2. Features and Benefits (approx. 300 words)Detail the key features and benefits offered by this particular actuator gearbox. Highlight its unique characteristics, such as precision engineering, high torque capacity, compact design, and ease of installation. Discuss how these attributes result in improved performance, reduced downtime, increased efficiency, and cost-effectiveness for industries utilizing the product.3. Industry Adaptation and Feedback (approx. 200 words)Explore how various industry sectors have embraced the actuator gearbox and their feedback on its performance. Interview professionals, engineers, or industry experts who have implemented the product in their operations. Collect their experiences, opinions, and case studies to showcase the positive impact of the actuator gearbox on different industrial applications.4. Technological Advancements and Future Prospects (approx. 150 words)Highlight the ongoing research and technological advancements in actuator gearbox technology. Discuss potential future developments, such as integrating advanced sensors, enhanced connectivity, or increased automation capabilities. Delve into the potential impact these advancements may have on industries, including improved production efficiency, reduced energy consumption, or expanded application areas.Conclusion:With its remarkable features and proven benefits, the Actuator Gearbox introduced by [Company Name] is revolutionizing industries across the board. Its ability to facilitate precise control and motion transmission in various applications ensures enhanced productivity and efficiency. As the product continues to gain traction and evolve, the future of industrial processes looks more robust and optimized than ever before.[Please note that this is a generalized template and may require customization and incorporation of the actual company introduction and specific news content for completion.]

Discover the Relevance and Benefits of Rack And Worm Gear Systems

Title: Innovative Solution Revolutionizes Gear Systems: Rack And Worm Gear Pair Redefines Efficiency and PerformanceIntroduction:In an era of technological advancements, companies constantly strive to innovate and provide breakthrough solutions that reshape industries. One such company, dedicated to engineering excellence, has introduced a game-changing product: a cutting-edge implementation of Rack And Worm Gear (name removed) technology. This new development brings forth unparalleled efficiency and performance in gear systems, solidifying the company's position as a leader in the field. Let us delve deeper into this remarkable development and explore its potential impact across various industries.Section 1: Understanding Rack And Worm Gear TechnologyThe Rack And Worm Gear technology, pioneered by the company (name omitted), is a powerful force transmission system. It comprises a worm gear and a corresponding horizontal rack, ensuring torque conversion and motion transfer. This impressive design enables its application in diverse sectors, from automotive to industrial machinery, proving its versatility and adaptability.Section 2: Unveiling the Key Advantages2.1 Exceptional Efficiency:With a unique tooth profile and optimized gear geometry, the innovative Rack And Worm Gear solution exhibits exceptional efficiency. The gear system demonstrates reduced power loss, resulting in heightened performance and increased overall efficiency. This advancement translates to significant cost savings and resource conservation for industries adopting the technology.2.2 Enhanced Precision:The meticulous engineering behind Rack And Worm Gear technology guarantees high-precision motion control. Its capability to achieve smooth and accurate positioning facilitates seamless operation in various applications. Additionally, the gear system's self-locking mechanism reduces back-driving, ensuring stability and security, particularly in critical operations and heavy machinery.2.3 Increased Load Capacity:The new Rack And Worm Gear design revolutionizes load-bearing capabilities. Its superior load-carrying capacity allows for the handling of heavier loads, boosting operational capabilities for industries such as manufacturing, construction, and logistics. By providing robust gear systems that can withstand substantial stress, the technology ensures optimal performance, reliability, and longevity.Section 3: Applications Across Industries3.1 Automotive Industry:The automotive sector can significantly benefit from the implementation of Rack And Worm Gear technology. This innovative gear system offers precise steering control, ensuring improved responsiveness and accuracy. Furthermore, its exceptional efficiency enhances fuel economy, reducing environmental impact and meeting ever-stringent industry regulations.3.2 Robotics and Automation:In the realm of robotics and automation, precision and reliability are vital. Rack And Worm Gear technology provides an ideal solution for these demanding applications. The gear system's self-locking feature guarantees secure operation, enabling safe and precise movement control essential in advanced robotic systems.3.3 Industrial Machinery:Industries that rely on large-scale machinery, such as manufacturing and construction, can leverage the robustness and load-bearing capabilities of Rack And Worm Gear technology. Its ability to handle heavy loads, combined with enhanced precision, allows for smoother operations, improved productivity, and reduced downtime.Section 4: Company's Dedication to InnovationThe company's introduction of the Rack And Worm Gear technology exemplifies its commitment to driving innovation in the field. As a leader in the industry, the company's state-of-the-art research and development division continually explores new possibilities, pushing the boundaries of gear systems. With a focus on customer-centric solutions, the company aims to revolutionize industries while addressing the unique needs of its clients.Conclusion:The advent of Rack And Worm Gear technology represents a significant breakthrough in the realm of gear systems, promising enhanced efficiency, precision, and load-bearing capacities. As industries constantly strive to improve performance and reduce operational costs, this innovation presents an invaluable solution. The company (name removed) continues to pave the way for advancements in the field, solidifying its position as an industry leader committed to engineering excellence and customer satisfaction.

Understanding the benefits of Worm and Helical Gears in mechanical systems

Worm And Helical Gear- Elevating the Standards of Gear TechnologyGear technology has long been an integral part of various industries, from automotive to manufacturing, playing a crucial role in transferring power and motion. In this regard, the development and production of high-quality gears are essential for efficient and reliable machinery and equipment. One company that has demonstrated a commitment to excellence in gear technology is [Company Name].[Company Name] is a leading manufacturer of worm and helical gears, offering a wide range of products that are designed and engineered to meet the diverse needs of its customers. With a focus on innovation and precision, the company has established itself as a trusted provider of gear solutions for a variety of applications, including industrial machinery, automotive systems, and power transmission equipment.Worm gears are known for their ability to provide high gear reduction, making them ideal for applications that require smooth and quiet operation. On the other hand, helical gears are renowned for their efficiency and durability, offering high load-carrying capacity and smooth meshing characteristics. By combining these two types of gears, [Company Name] has been able to deliver gear solutions that not only meet but exceed the expectations of its customers.The company's dedication to quality and performance is reflected in its state-of-the-art manufacturing facilities and advanced engineering capabilities. With a team of skilled engineers and technicians, [Company Name] is able to design and produce gears that are tailored to meet the specific requirements of its customers, ensuring optimal performance and reliability.Furthermore, [Company Name] is committed to staying ahead of the curve when it comes to gear technology. The company invests in research and development to continuously improve its products and explore new opportunities in gear design and manufacturing. This proactive approach has allowed [Company Name] to introduce innovative gear solutions that set new standards in the industry.In addition to its technical expertise, [Company Name] also places great emphasis on customer satisfaction. The company works closely with its clients to understand their unique needs and challenges, providing personalized solutions that address their specific requirements. This customer-centric approach has earned [Company Name] a reputation for being a reliable and responsive partner in the gear manufacturing industry.Beyond its commitment to quality and customer service, [Company Name] takes its responsibility to sustainability and environmental stewardship seriously. The company adheres to strict environmental standards in its manufacturing processes and continuously seeks ways to minimize its environmental impact. By integrating sustainable practices into its operations, [Company Name] aims to contribute to a greener and more sustainable future.As [Company Name] continues to grow and expand its presence in the gear manufacturing industry, the company remains dedicated to upholding its core values of excellence, innovation, and integrity. With a focus on delivering superior gear solutions and exceeding customer expectations, [Company Name] is poised to remain a leader in gear technology for years to come.In conclusion, [Company Name] stands out as a premier provider of worm and helical gears, offering innovative solutions that elevate the standards of gear technology. With its commitment to quality, customer service, and sustainability, the company has solidified its position as a trusted partner for gear manufacturing needs. As industries continue to evolve, [Company Name] remains at the forefront, delivering gear solutions that empower machinery and equipment to perform at their best.